Advanced Fully Automatic Sewage Treatment Systems Sequence Batch Reactor (SBR) Technology - Capacity Starts from 1KLD Onwards

The SBR technology is a common and widely used water treatment system. Also known as Sequencing batch reactor (SBR) water treatment systems, these are highly powerful and efficient water treatment systems. SBR water treatment systems are widely used because it is a proven technology which has minimal to no maintenance thus becoming cost-effective.

To talk about some of the distinct properties, Biological processes and high-quality product generation are two of the prominent factors which make SBR water treatment systems stand out from others.

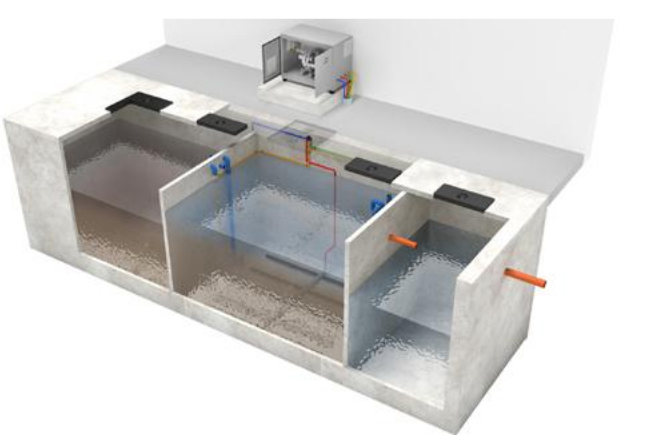

We have slick designed SBR waste water treatment systems which are designed fully advanced and automatic system to deliver high output while being energy & cost efficient.

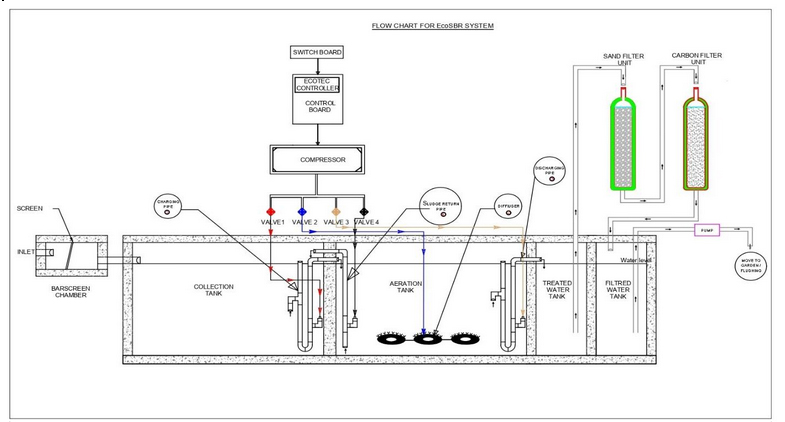

To talk about its working method, The sequencing batch reactor (SBR) is a fill-and-draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor through intelligently designed airlift pumps, treated to remove undesirable components, and then discharged through airlift mechanism. Equalization, aeration, and clarification can all be achieved using a single batch reactor. To optimize the performance of the system, two or more batch reactors are used in a predetermined sequence of operations. SBR systems have been successfully used to treat both industrial and Residential wastewater. They are uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions.

SBR Treatment Process

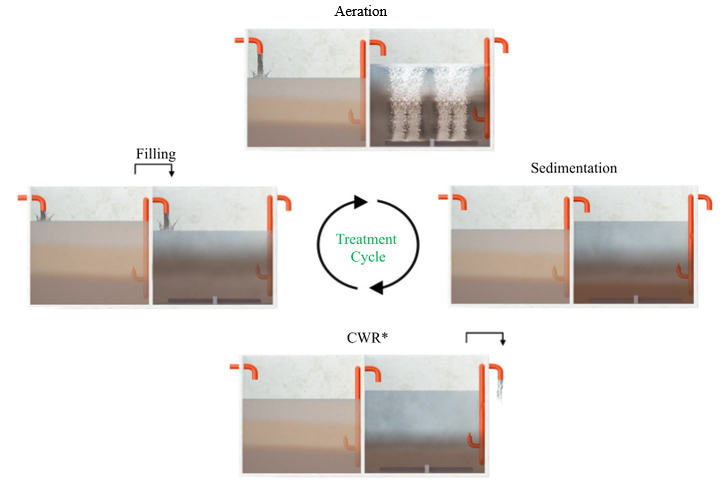

Aeration based biological process Operation in 4+1 steps

- Filing / Sewage transfer

- Aeration / Reaction

- Settling

- Clearwater Removal

- Excess Sludge Removal

Single blower is replacing all mechanical pumps for entire plant

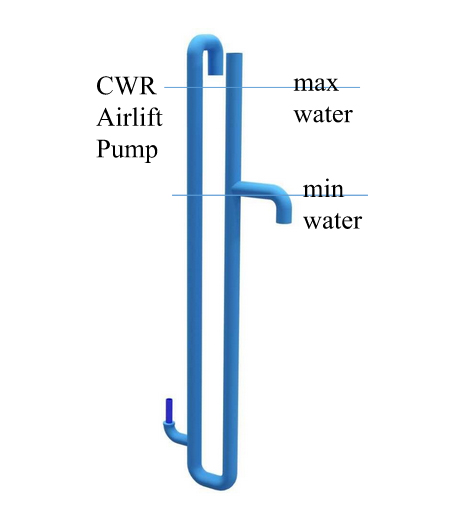

SBR Air-lift Technology!

Airlift mechanism replace pump used for

- Raw Sewage waste water transfer from collection tank to aeration tank

- Decanting from aeration tank to pre filtered water tank

- Excess Sludge removal from aeration tank to sludge holding tank

Advantages of Airlift mechanism

- Single compressor is used for filling, aeration, decant, sludge return process

- No electric power connection needed inside the tank

- No need of services for pump in underwater

- High volume of waste water transfer in a short operation period

- Does not need any service in it lifetime

- Does not clog at all

| SBR Treatment | |||

| Sewage Parameter | At Inlet | At Outlet | EcoSBR Efficiency |

| COD(Chemical Oxygen Demand) | <800 mg/l | <40 mg/l | 95% |

| BOD(Biochemical Oxygen Demand) | <400 mg/l | <10 mg/l | 98% |

| SS (Suspended Solids) | <467 mg/l | <20 mg/l | 96% |

| N (Total Nitrogen) | <73 mg/l | <3.5 mg/l | 95% |

SBR Features

- No need of plant operator

- Very low power consumption

- Airlift mechanism replaces of all mechanical pumps in treatment process

- IOT means accessing every plant from centralized location

- System will handle under load and overload

- Low sludge volume production

- Suitable for varying load (Industries)

- Controller records and disruption to operation

- Eco Save mode saves further energy during vacation

- No need for UF and complicated filters

- Treatment meets PCB norms and beyond

- Easy to troubleshoot

Flowchart

IOT Controller